As global data demands grow at an unprecedented pace, companies are racing to build reliable, scalable and energy efficient data centers. Cloud computing, AI workloads and the rapid digitalization of enterprises require new facilities to be delivered faster and with stronger structural performance than ever before. For developers, investors and operators, delays can directly translate to substantial financial loss. Every month a data center is not online, significant revenue and operational capacity are left unused.

In this challenging environment, precast concrete has emerged as a powerful solution for achieving speed, consistency and structural reliability. Combined with a precise structural engineering approach and detailed BIM coordination, precast enables fast-track delivery while ensuring high quality and compliance with strict technical demands.

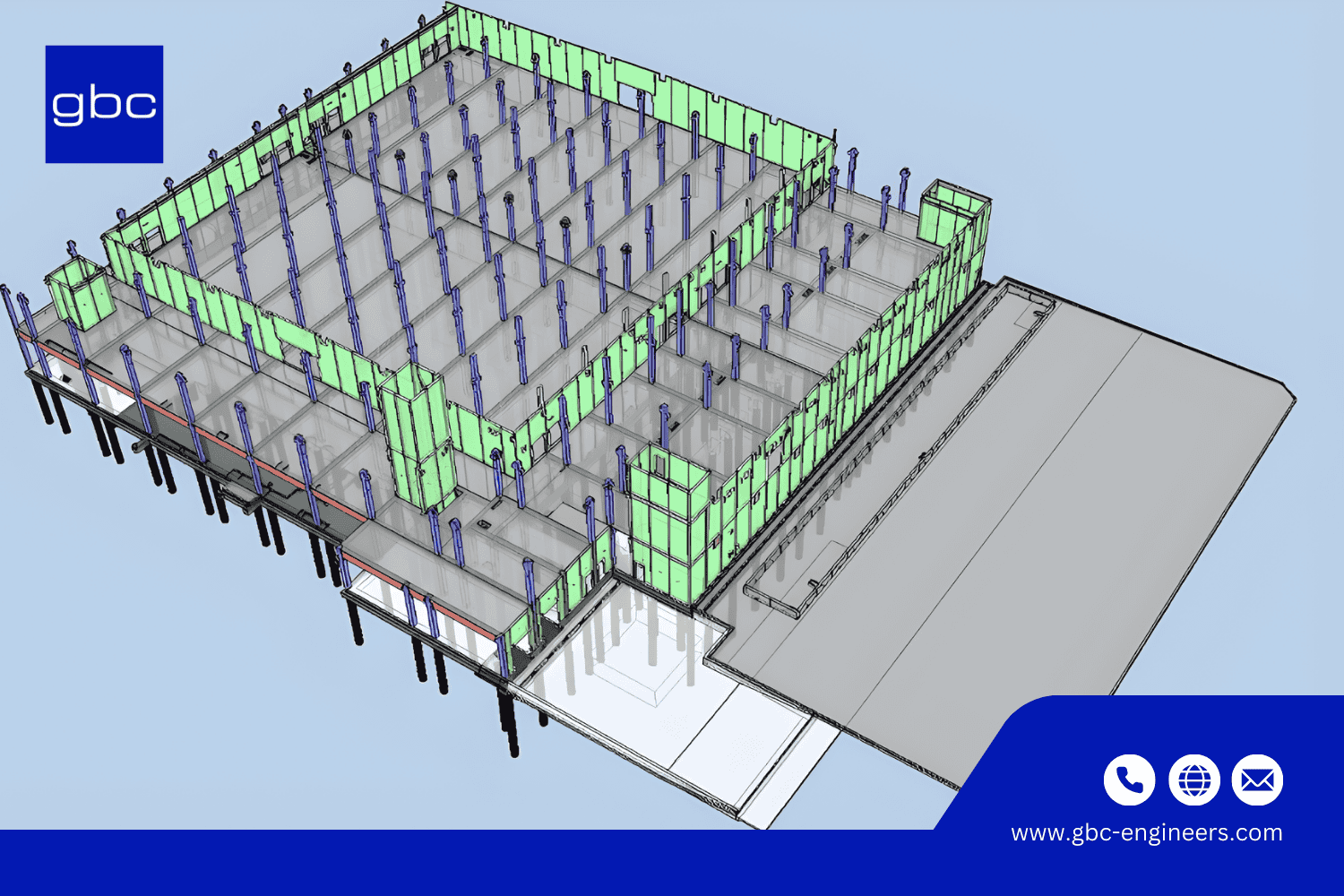

This article explains how precast supports quick and easy construction for modern data centers and highlights the BER22 project, where gbc engineers played a key role in structural design and BIM modelling.

Why Data Centers Need Faster and More Efficient Construction

The digital economy is expanding dramatically. Businesses rely on data centers to store, process, and distribute data at high speed. Hyperscalers, colocation providers and enterprise clients all demand facilities that are safe, resilient and future proof. But the timelines are becoming tighter.

Traditional cast in place concrete is time consuming due to formwork, curing periods and weather dependencies. It requires large on-site labour teams, complex planning and typically results in longer construction timelines.

Precast concrete, on the other hand, offers predictable fabrication, quick installation, and repeatable quality. When paired with a detailed structural engineering concept, it helps reduce bottlenecks and accelerate project delivery significantly.

This is why precast is increasingly chosen for large data center campuses in Europe, including projects delivered by gbc engineers through its data center Structural Engineering Services.

Why Precast Concrete Is Ideal for Modern Data Centers

Precast concrete is not just a construction method. It is a strategic enabler for fast and controlled structural delivery. For data centers, which require high load capacities, large spans and precise coordination with heavy cooling and power systems, precast elements offer several technical and commercial advantages.

- Speed of Construction

Precast elements are produced in the factory while site preparations, foundation works and MEP coordination happen in parallel. This overlapping workflow shortens the overall schedule. Installation on site is also faster because elements arrive ready to assemble, reducing waiting time and eliminating curing delays.

- High Load Capacity and Excellent Structural Performance

Data centers host equipment with extremely high floor loads, especially in server halls, UPS rooms and battery energy storage areas. Precast beams, columns, wall panels, and TT slabs offer high stiffness and controlled deflection, supporting long term stability and vibration performance.

- Precision and Repeatability

Factory production ensures high dimensional accuracy. For data centers, the repetitive structural grid makes precast a perfect match. Consistent element geometry helps maintain alignment for racks, cable trays, piping, and mechanical platforms.

- Improved Safety and Reduced On Site Labour

With less formwork and fewer lifting steps, the construction site becomes cleaner and safer. Smaller teams can install large components in a short time, reducing coordination complexity.

- Works Seamlessly with BIM Planning

Modern data center projects rely heavily on BIM coordination. Precast modelling within BIM ensures clash-free interfaces between structural elements, cooling systems, cable trays, risers, and fire compartments. At our company, structural BIM models are used throughout all phases to support design clarity and fabrication.

The Role of Data Center Structural Design in Fast Track Delivery

Structural engineering is the foundation of every fast-track data center project. When structural decisions are made early and aligned with precast technology, the entire project benefits from:

- Predictable construction schedules

- Better cost control

- Higher safety and reliability

- Improved coordination with architectural and mechanical layouts

Integrating Cooling Infrastructure Requirements

Data centers have a complex mechanical ecosystem that impacts the structure. Heavy rooftop cooling units, chilled water pipes, dry coolers, cable trays and air handling units all require precise load planning. Precast elements must include embeds, openings, and support for these systems. This coordination is handled smoothly through BIM, reducing rework on site.

Fire Resistance and Structural Redundancy

Precast concrete achieves excellent passive fire performance, which is crucial for data centers that must ensure continuous operation. The structural design must also include redundancy to maintain load paths even under failure conditions.

With high precision structural modeling, gbc engineers support clients to integrate fire compartments, escape routes and penetrations within structural elements to meet strict regulations.

Case Study: BER22 Data Center – Fast Construction through a Precast Strategy

The BER22 Data Center is an excellent example of how precast enables fast, efficient and safe construction.

Located in Germany, the facility required a structural system that could support high loads, integrate with heavy cooling equipment and meet tight delivery deadlines. gbc engineers were entrusted with structural design, structural modelling, and BIM coordination for this project.

Why Precast Was Selected for BER22

Precast offered several advantages such as:

- Fast erection sequence for the building core and superstructure

- Ability to fabricate large TT slabs and beams while foundations were ongoing

- High uniformity to match repetitive data hall layouts

- Reduced risk of construction delay due to weather

Types of Precast Elements Used

Typical precast elements applied in data center projects like BER22 include:

- Precast columns and beams

- TT slabs for long span server areas

- Precast shear walls and stair cores

- Hollow core or solid slabs for technical and office areas

- Precast facade panels where applicable

These components allow consistent geometry, clean installation, and robust support for high loads.

Structural Challenges and Solutions

Heavy Load Requirements

Data halls require strong and rigid floor systems. Through detailed structural calculations, the precast elements were optimized for high live loads.

MEP Interference and Openings

All openings for cables, pipes and ventilation were coordinated in the BIM model and reflected directly in the precast shop drawings.

Tight Construction Timeline

Precast helped reduce time significantly by enabling parallel engineering, fabrication and installation workflows.

Project Results

- Faster schedule and earlier commissioning

- High quality structure with minimal rework

- Reduced risk during construction

- Greater predictability for the client

With this approach, BER22 achieved a reliable and scalable structure suitable for future expansion.

Precast vs Traditional Construction for Data Centers

Below is a simple comparison that decision makers can use when evaluating structural strategies:

| Construction speed |

Very fast due to prefabrication |

Slow because of curing time |

| On site labour |

Reduced, safer |

High manpower required |

| Quality control |

Consistent, factory-controlled |

Dependent on site conditions |

| Weather impact |

Minimal |

Significant risk of delay |

| Cost predictability |

High |

Moderate |

This comparison shows why many leading developers are shifting toward precast for large scale facilities.

How gbc engineers Supports Precast Based Data Center Projects

gbc engineers specialises in structural engineering and BIM planning for complex buildings, including high density and hyperscale data centers. The company supports clients at every stage, from concept planning to detailed precast modelling and installation guidance.

Key capabilities include:

- Full structural engineering for data centers

- BIM coordination with architectural

- Precast element modelling and connection detailing

- Foundation design for high loads and vibration control

- Value engineering for cost and material optimisation

- Construction phase support for installation sequencing

For sector specific solutions such as bridges, high rise buildings or industrial facilities: https://gbc-engineers.com/segments

Conclusion: Precast Enables Faster, Safer and More Reliable Data Center Construction

As the demand for data centers continues to grow, owners and developers need solutions that reduce time, minimize risks, and deliver reliable performance. Precast concrete offers all these advantages. When combined with precise structural engineering, BIM coordination and proactive planning, precast becomes a powerful strategy for fast-track delivery.

The BER22 project demonstrates how this method can achieve impressive results. Through its experience in structural design and BIM modelling for data centers across Europe and Asia, gbc engineers continues to support clients with scalable, efficient and resilient solutions.

If you are planning a new data center or looking to optimize your structural system, the team at gbc engineers is ready to support your project.

|

About us

gbc engineers

is an international engineering consultancy with offices in Germany, Poland, and Vietnam, having delivered 10,000+ projects worldwide. We provide services in structural engineering, data center design, infrastructure and bridge engineering, BIM & Scan-to-BIM, and construction management. Combining German engineering quality with international expertise, we achieve sustainable, safe, and efficient solutions for our clients.

|